RepMold

Introduction

Manufacturing today demands speed, accuracy, and repeatability—qualities that can make or break product success. As industries shift toward advanced prototyping and high-precision mass production, RepMold has emerged as a powerful solution. Whether you’re in automotive, medical devices, consumer products, aerospace, or industrial design, RepMold provides a reliable method for creating exact, repeatable molds with exceptional surface detail.

In today’s competitive production landscape, companies increasingly rely on mold replication, precision molds, rapid mold making, and CNC mold tooling to shorten production cycles and improve efficiency. RepMold connects these advanced processes into one streamlined solution.

What Is RepMold?

RepMold refers to an advanced mold-replication technology that uses high-precision processes to create molds, dies, or tool cavities with extreme accuracy. These molds are typically produced using CNC machining, resin casting, silicone molding, or metal additive manufacturing.

RPM technologies allow manufacturers to:

- Replicate master patterns

- Produce mold sets quickly

- Ensure consistent quality across thousands of units

- Reduce production downtime

- Accelerate prototype-to-production cycles

It has become especially important in modern manufacturing where short-run and customized parts must still meet strict dimensional tolerances.

This makes RPM essential in industries that depend on prototyping molds, duplication molds, and silicone mold manufacturing.

How RepMold Works: Step-by-Step Process

RepMold technology may vary depending on the material and industry, but the core workflow remains similar.

1. Creating the Master Pattern

Everything begins with a “master.” This could be:

- A 3D-printed part

- A CNC-machined part

- A handmade model

- An original product

The master must be dimensionally accurate because the mold captures every detail—including imperfections.

2. Surface Preparation

To ensure smooth mold release and quality reproduction:

- The master is polished

- Release agents are applied

- Alignment keys are created if the mold has multiple parts

This step is crucial for accurate mold duplication and long-term mold performance.

3. Mold Material Selection

Choosing the right mold material depends on the production goal:

| Material | Best For | Key Benefit |

|---|---|---|

| Silicone | Prototyping, flexible molds | High detail reproduction |

| Epoxy Resin | Mid-volume runs | Durable and stable |

| Aluminum | High-volume industrial molds | Long life, high precision |

| Steel (H13, P20) | Injection molding | Extreme durability |

4. Mold Pouring or Machining

Depending on the RPM technique, the mold cavity is formed by:

- Pouring silicone around the master

- Casting resin

- CNC machining metal blocks

- Laser sintering for metal molds

These methods support detailed features essential in rapid mold making workflows.

5. Curing or Finishing

The mold is hardened using:

- Heat curing

- UV curing

- Chemical curing

- Post-machining

6. Mold Testing

Before production starts, the mold undergoes:

- Fit checks

- Dimensional accuracy tests

- Sample production runs

This ensures durability and consistency for large-scale mold replication.

Why RepMold Matters: Key Benefits

High Precision

RepMold processes capture extremely fine features—down to microns. Industries like medical and aerospace rely on this accuracy for safety and compliance.

Faster Production Cycles

Companies using advanced replication molds reduce prototype lead time by 30–60%.

Examples:

- A consumer electronics brand cut its R&D time by 45%.

- An automotive supplier produced spare parts 3× faster.

These improvements come from using optimized precision molds and CNC mold tooling.

Cost Efficiency

RepMold reduces:

- Tooling costs

- Trial-and-error waste

- Production downtime

- Labor requirements

Some companies report savings of up to 40% compared to traditional tooling.

Repeatability

Once a high-quality mold is produced, manufacturers can generate thousands—or even millions—of identical parts.

Design Flexibility

RPM supports:

- Complex geometries

- Undercuts

- Multi-part assemblies

- Prototyping revisions

This makes it ideal for rapid product innovation and efficient prototyping mold production.

Applications of RepMold Across Industries

Consumer Product Manufacturing

RPM helps brands produce durable plastic parts at scale, especially through rapid duplication molds.

Automotive

Used for:

- Interior components

- Small mechanical parts

- Dashboard molds

- Rubber seals

Short-run production is especially cost-effective with RepMold.

Aerospace

Precision components such as turbine blade prototypes rely on high-accuracy molding.

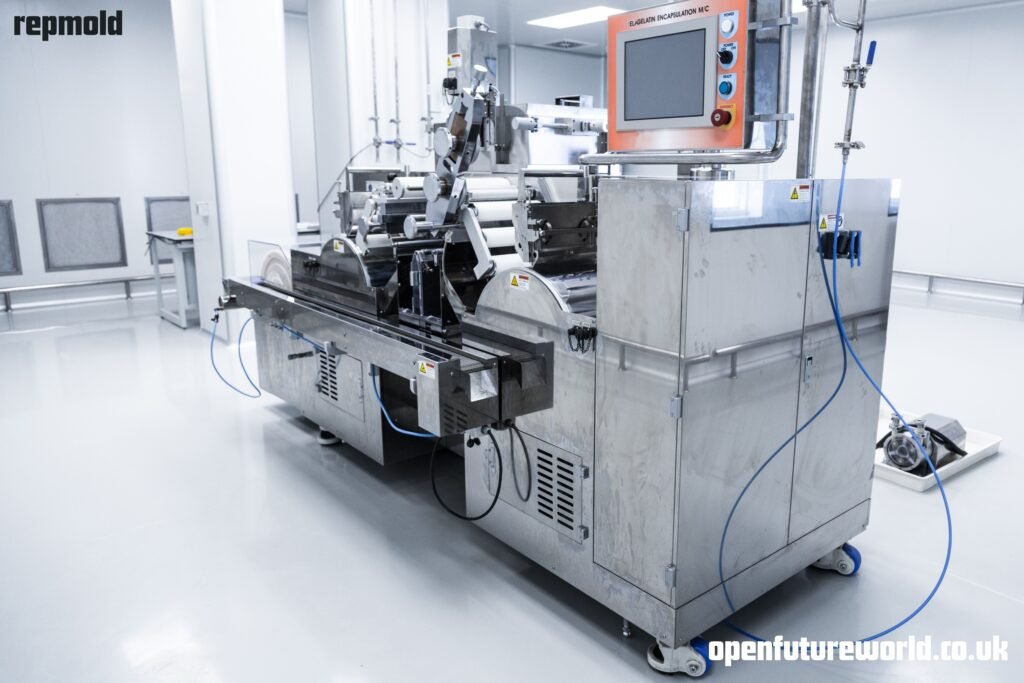

Medical Devices

RPM ensures compliance and precision for:

- Surgical tools

- Prosthetics

- Diagnostic equipment casings

Accurate silicone mold manufacturing is vital for detailed medical components.

Industrial Machinery

Gears, housings, connectors, and replacement parts can all be reproduced accurately.

Jewelry and Miniature Art

Artists use silicone RepMolds to produce exact replicas with fine details.

RepMold Techniques: Which Method Is Best?

1. Silicone RepMolding

Best for:

- Master pattern duplication

- Flexible molds

- Prototyping

Perfect for high-detail mold replication.

2. CNC Metal Mold Machining

Ideal for:

- Injection molding

- High-volume runs

- Durable tooling

Commonly used for industrial precision molds.

3. 3D Printing + Mold Casting

A hybrid method:

- 3D print master

- Use RPM to create molds

Ideal for rapid mold making and fast prototyping.

4. Metal Additive Manufacturing for Molds

Used in aerospace and medical manufacturing.

Advantages:

- Internal cooling channels

- Complex shapes

- Reduced machining time

Cost of RepMold Manufacturing

| Mold Type | Cost Range | Applications |

| Silicone Mold | $50–$500 | Prototyping |

| Resin Mold | $100–$900 | Small batch runs |

| Aluminum Mold | $800–$5,000 | Mid-volume production |

| Steel Mold | $3,000–$50,000+ | High-volume injection |

Companies using RPM for spare parts see 20–35% overall cost reduction annually.

How to Choose a RepMold Supplier

When selecting a mold manufacturer, consider:

- Industry experience

- Certifications (ISO 9001, ISO 13485)

- Prototyping capabilities

- Quality control processes

- Material sourcing

Choose a partner strong in CNC mold tooling and precision mold engineering.

Common Mistakes to Avoid

- Using low-quality master patterns

- Selecting the wrong mold material

- Ignoring draft angles

- Poor surface preparation

- Not testing molds before production

The Future of RepMold Technology

Trends shaping the industry:

- AI-assisted mold design

- Automated CNC mold shops

- High-resolution resin 3D printers

- Digital twins

- Smart molds with sensors

These innovations will enhance mold replication accuracy and reduce production time.

Conclusion

RepMold is transforming how companies design, test, and manufacture products. Whether you’re building medical devices, automotive parts, consumer goods, or industrial machinery, this technology offers unmatched precision, speed, and cost efficiency.

If you want the best guidance on mold design and manufacturing—contact us today, explore our services, or read more from our knowledge hub.

FAQs

What is RepMold used for?

RepMold is used for creating high-precision molds for manufacturing, prototyping, and mass production across industries like automotive, aerospace, medical, and consumer goods.

How long does a RepMold last?

Silicone molds last 20–50 uses; steel molds can last hundreds of thousands of cycles.

Is RepMold good for prototyping?

Yes. RPM is ideal for fast, cost-effective prototypes with excellent detail.

Can RepMold copy fine details?

Yes. It captures features down to microns, making it perfect for detailed parts.

How much does RepMold cost?

From $50 to $50,000+, depending on material and complexity.